Hongxin Steels: Hot Work Mastery

2025-06-04 19:49In the demanding world of hot work tooling, where steel must endure extreme temperatures, repeated impact, and punishing cycles, Hongxin stands as a beacon of reliability and innovation. As a premier tool steel manufacturer based in China, Hongxin specializes in crafting 5CrNiMo hot work steel and alloy mold steel plates—materials renowned for their toughness, thermal stability, and resistance to cracking under pressure. For wholesalers and industrial partners seeking robust, custom die steel solutions, Hongxin’s expertise redefines the standards of quality and performance.

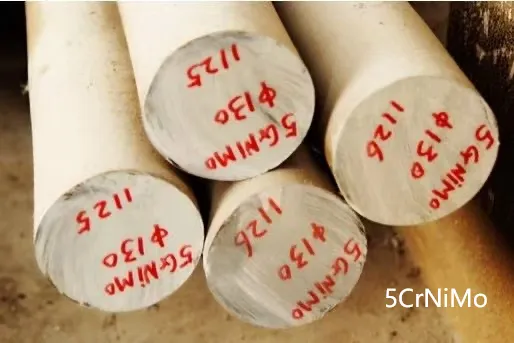

Why 5CrNiMo? The Backbone of Hot Work Resilience

5CrNiMo steel, a Chinese-grade equivalent to H11 in international standards, is the go-to choice for die-casting, forging, and extrusion tools. Its balanced composition of chromium, nickel, and molybdenum ensures exceptional hardness retention at elevated temperatures (up to 550°C), along with superior toughness to resist thermal shocks. Hongxin’s proprietary refining processes elevate these traits further, optimizing grain structure and reducing impurities to enhance fatigue resistance. For wholesale die steel suppliers, this translates to fewer tool failures, longer service life, and cost savings for end-users.

Custom Alloy Mold Steel Plates for Tailored Needs

Hongxin understands that industrial demands vary widely, from precision die-casting molds to heavy-duty forging dies. The company’s strength lies in its ability to deliver custom alloy mold steel plates tailored to specific applications. Whether a client requires 5CrNiMo steel with adjusted carbon content for enhanced toughness or alloy plates with tailored thicknesses and surface finishes, Hongxin’s engineers collaborate closely to refine steel compositions and processing parameters. This flexibility ensures that every batch meets—or exceeds—the unique demands of industries like automotive, aerospace, and consumer goods manufacturing.

Precision Engineering from China’s Steel Hub

Headquartered in China, Hongxin leverages advanced metallurgical expertise and cutting-edge technology. Its facilities feature vacuum induction melting (VIM) units, electroslag remelting (ESR) furnaces, and precision rolling mills, enabling rigorous control over steel purity, microstructure, and dimensional accuracy. This commitment to quality has earned Hongxin certifications like ISO 9001 and TS 16949, assuring global partners of consistency and compliance. For tool steel manufacturers, such investments in infrastructure and expertise are the cornerstones of trust and reliability.

Sustainability and Efficiency in Every Plate

In an era where environmental stewardship is paramount, Hongxin integrates sustainability into its operations. The company optimizes melting and refining processes to minimize energy consumption and waste, while recycling scrap steel to reduce raw material demand. Additionally, Hongxin’s 5CrNiMo and alloy mold steel plates are engineered for durability, reducing the frequency of replacements and associated carbon footprints. For wholesale die steel suppliers, this eco-conscious approach aligns with the growing demand for greener industrial solutions.

Global Reach, Local Partnerships

Hongxin’s clientele spans continents, from North American die-casters to European mold makers. The company’s deep understanding of international standards—such as AISI, JIS, and DIN—ensures seamless compatibility with global manufacturing workflows. For tool steel manufacturers, this global perspective is invaluable, as it allows Hongxin to anticipate market trends and adapt rapidly to regional preferences. Whether a client needs a prototype batch or bulk orders, Hongxin’s scalable processes deliver on time and within specification.

Collaborative Innovation for Tomorrow’s Challenges

Hongxin views its role as more than just a supplier—it’s a partner in progress. The company’s R&D team actively engages with clients to co-develop next-generation steel alloys, pushing the boundaries of what’s possible in hot work applications. For wholesale die steel suppliers, such collaborations foster innovation and differentiation in competitive markets.

Conclusion

In the high-stakes world of hot work tooling, Hongxin’s 5CrNiMo hot work steel and alloy mold steel plates are synonymous with excellence. As a trusted tool steel manufacturer in China, Hongxin empowers wholesalers and industrial partners with custom, sustainable solutions that drive efficiency and profitability. With a focus on precision, innovation, and client-centric service, Hongxin is not just meeting industry demands—it’s shaping the future of die steel manufacturing.