High-Performance Hot Work Steel

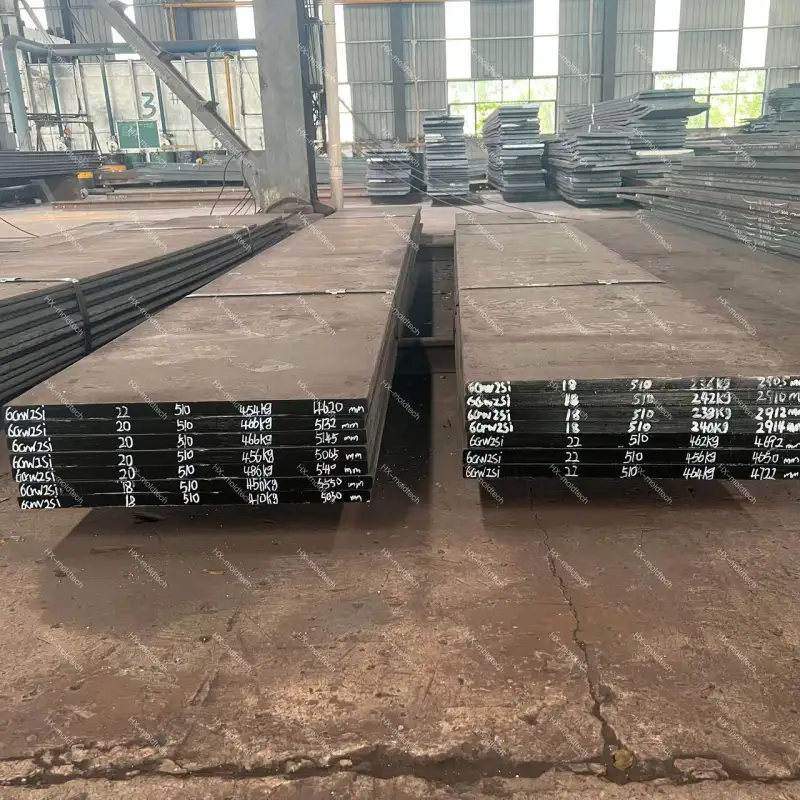

2025-05-13 21:17In the demanding world of industrial manufacturing, hot work tool steel plays a crucial role in applications involving high temperatures, pressure, and wear resistance. Among the most widely used grades is 6Cr W2Si hot work tool steel, known for its excellent toughness, thermal fatigue resistance, and dimensional stability under extreme conditions. Complementing this is DIN 1.2550 tool steel bar, a European standard alloy valued for its balanced performance in hot working environments.

China has become a global leader in the production of tool steel, offering high-quality materials that meet international standards while maintaining competitive pricing. Among the top names in this sector is Hongxin, a reputable brand among hot work tool steel manufacturers, known for delivering both standard and custom tool steel solutions tailored to specific industrial needs.

Why Choose 6CrW2Si and DIN 1.2550 Tool Steels?

6CrW2Si hot work tool steel is a Chinese-grade alloy composed of chromium, tungsten, and silicon—elements that enhance hardness, heat resistance, and wear protection. It is commonly used in forging dies, hot extrusion tools, and press molds where prolonged exposure to elevated temperatures occurs.

Similarly, DIN 1.2550 tool steel bar, also known as 55NiCrMoV7, offers superior shock absorption and resistance to softening at high temperatures. This makes it ideal for applications like die casting, hot shear blades, and trimming dies.

Selecting the right hot work tool steel ensures not only longer tool life but also reduced downtime and maintenance costs—critical factors in high-efficiency production lines.

Hongxin: A Trusted Manufacturer in China

As one of the leading hot work tool steel manufacturers in China, Hongxin specializes in producing a wide range of high-performance tool steels, including 6CrW2Si tool steel China and DIN 1.2550 steel bar. With years of metallurgical experience and modern processing facilities, Hongxin delivers products that meet stringent international standards such as AISI, JIS, and ISO.

What sets Hongxin apart is its commitment to custom tool steel manufacturing. Whether you need unique dimensions, specialized heat treatment, or tailored mechanical properties, Hongxin collaborates closely with clients to provide precise solutions that align with their operational requirements.

The company’s advanced production process includes electric arc furnaces, vacuum heat treatment systems, and CNC machining centers, ensuring every batch of tool steel China meets tight tolerances and superior mechanical characteristics.

Applications Across Key Industries

Hot work tool steels are essential across various sectors:

Metal Forging: Used in hammer dies and upset forging dies exposed to repeated impacts and high temperatures.

Die Casting: Employed for molds that must withstand molten metal injection without deformation.

Plastic Molding: Utilized in high-temperature injection molds requiring excellent polishability and corrosion resistance.

Automotive & Aerospace: Critical for precision components subjected to extreme stress and heat.

By choosing Hongxin, businesses gain access to a dependable supplier capable of supporting large-scale industrial operations with consistent quality and timely delivery.

Focus on Quality and Sustainability

Beyond product excellence, Hongxin emphasizes sustainability and continuous innovation. The company invests in energy-efficient melting technologies and waste recycling systems to reduce environmental impact.

All tool steel China products undergo strict inspection using spectrometers, hardness testers, and ultrasonic flaw detectors before shipment. These quality control measures have helped Hongxin achieve certifications such as ISO 9001 and SGS compliance, reinforcing its reputation as a premium tool steel manufacturer.

In today’s competitive industrial environment, having access to high-quality, custom tool steel is essential for maintaining efficiency and reliability. As a leading tool steel China supplier, Hongxin combines technical expertise, advanced production capabilities, and customer-focused service to deliver superior hot work tool steel solutions.

Whether you're sourcing 6CrW2Si hot work tool steel for forging applications or DIN 1.2550 tool steel bar for custom mold making, partnering with Hongxin ensures your project benefits from unmatched durability, precision, and performance—all backed by a proven track record in the global market.