DIN 1.2080 Alloy Mold Steel

DIN 1.2080 alloy mold steel is widely used in high-wear applications such as shear blades, stamping dies, and precision tooling, serving top-tier clients in automotive, electronics, and packaging industries. Our stock includes round bars (Ø8-350mm), plates (2-300mm thick), and custom slabs, enabling 24-hour rapid delivery to meet urgent demands.

- HONGXIN

- DAYE

- 30DAYS

- 8000TONS/MONTH

- Information

- Download

DIN 1.2080 Alloy Mold Steel

DIN 1.2080 alloy mold steel is a high-carbon, high-chromium alloy tool steel (1.90-2.20% C, 11-13% Cr) renowned for exceptional wear resistance and compressive strength. Its matrix, enriched with hard carbides, effectively resists abrasive and adhesive wear, making it ideal for high-stress, long-life precision tooling applications. After oil quenching or vacuum gas quenching (for small sections), it achieves a hardness of 58-64 HRC with excellent dimensional stability and durability. However, brittleness during hardening requires careful process control.

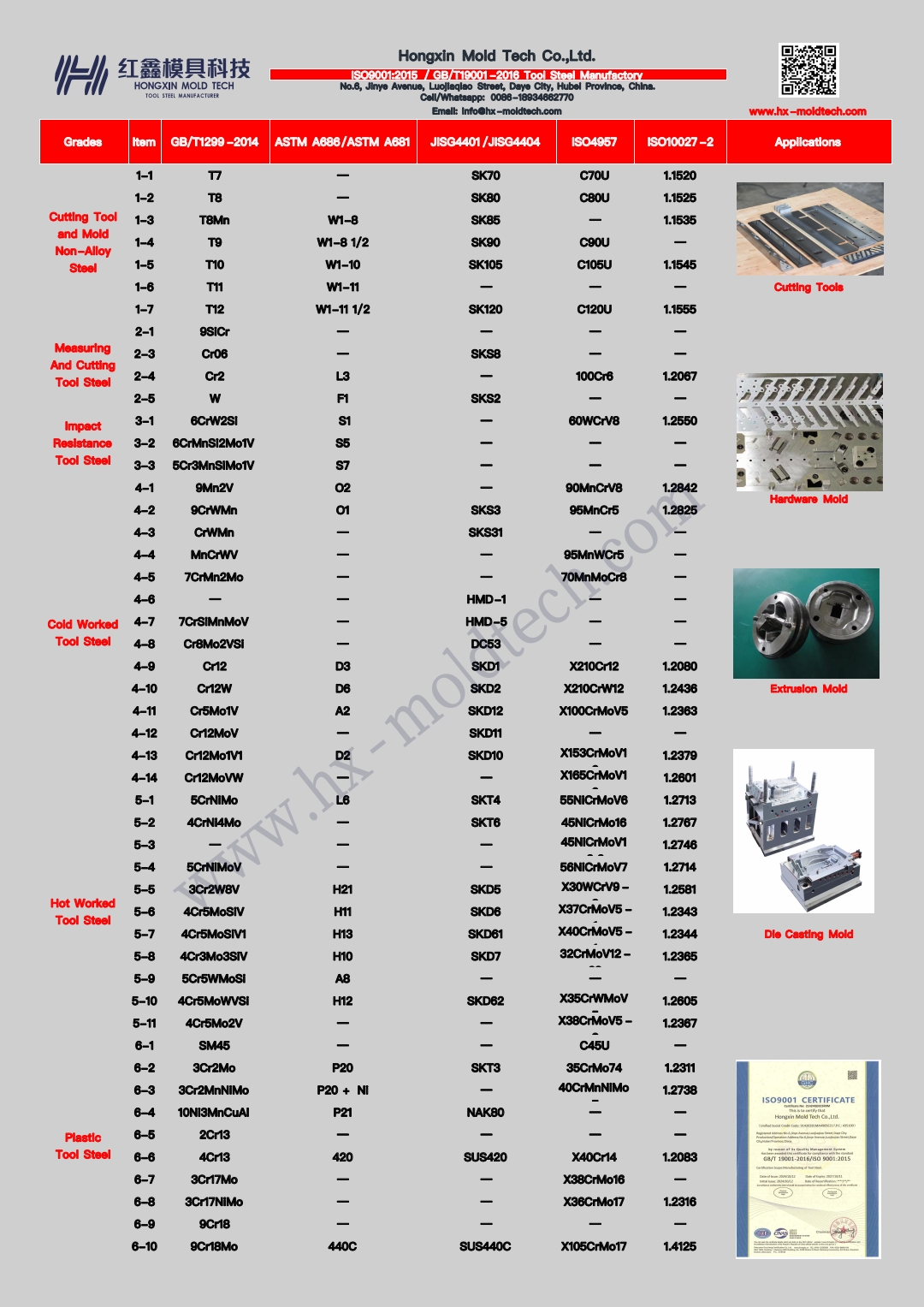

1. Chemical Composition & Equivalent Grades

| Grade | C | Mn | P | S | Si | Cr | V | W |

| DIN 1.2080 / X210Cr12 | 1.90-2.20 | 0.20-0.60 | / | / | 0.10-0.60 | 11.0-13.0 | / | / |

| ASTM D3 | 2.00-2.35 | 0.10-0.60 | 0.03 | 0.03 | 0.10-0.60 | 11.0-13.5 | ≤1.0 | ≤1.0 |

| GB/T Cr12 | 2.00-2.30 | ≤0.40 | 0.03 | 0.03 | ≤0.40 | 11.5-13.0 | / | / |

| JIS SKD1 | 1.90-2.20 | 0.20-0.60 | 0.03 | 0.03 | 0.10-0.60 | 11.0-13.0 | / | / |

2. Mechanical & Physical Properties

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered |

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled |

| Delivery condition | Forged; Hot rolled; Cold drawn |

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. |

| Payment terms | T/T;L/C;/Money gram/ Paypal |

| Trade terms | FOB; CIF; C&F; etc. |

| Packing | Standard Packages,or as Customers Request |

Delivery time | 30-45 days |

| Application | DIN 1.2080 alloy mold steel is suitable for applications such as complex blanking and formingtools for long runs and for hard and abrasive materials. |

3. Supply Specifications

Size | Round | Dia 12-500mm |

Plate/Flat/Block | Thickness 8mm-300mm | |

| Width 210mm-710mm | ||

| Process | EAF+LF+VD+Forged/Rolled+Heat treatment(optional) |

4. Heat Treatment Processes

Heat Treatment

DIN 1.2080 alloy mold steel requires hardening and tempering to achieve maximum properties. For maximum accuracy, the parts of D3 tool steel should be stress relieved after roughing operations. Stress should be relieved at 648°C (1200°F) for one hour and cooled slowly.

Annealing

DIN 1.2080 alloy mold steels uniformly to 850-870°C, soak thoroughly, then slow furnace cool at a rate of not more than 25°C per hour to 650°C. The parts may then be air cooled. This should result in a maximum hardness of brinell 248.

Tempering

DIN1.2080 alloy mold steel should be cooled to room temperature and should be tempered immediately. The parts should be placed in the tempering furnace and increased slowly to the desired tempering temperature. Tempering for 1 hour per inch of thickness is required.

Hardening

DIN1.2080 alloy mold steel is extremely sensitive to overheating during hardening – do not overheat.

Pre heat slowly to 800-850°C, the raise rapidly to 950-970°C and soak until completely equalised. Quench in oil.

5. Forging & Machining Guidelines

Forging Temperature: Preheat to 900-950°C; final forging ≥900°C. Use light initial blows to prevent cracking.

Grinding: Use CBN or diamond wheels with low-speed, fine-grit operations due to high carbide content.

6. Typical Applications

High-Wear Tools: Shear blades, blanking dies, stone-cutting tools.

Precision Forming: Deep drawing dies, pressure pads, high-wear plastic molds.

Sheet Metal Processing: Thin-sheet punches, paper/plastic cutting knives, profile rolls.

7. Why Choose Us?

As a leading manufacturer of DIN 1.2080 alloy mold steel, we offer:

Full Inventory: Round bars, plates, slabs – ready for fast delivery.

Certified Quality: Compliant with DIN/EN/ISO 4957, ASTM A681, and JIS G4404 standards.

Technical Support: Expert guidance on heat treatment and machining optimization.

Custom Solutions: Tailored dimensions, surface finishes, or pre-hardened materials.

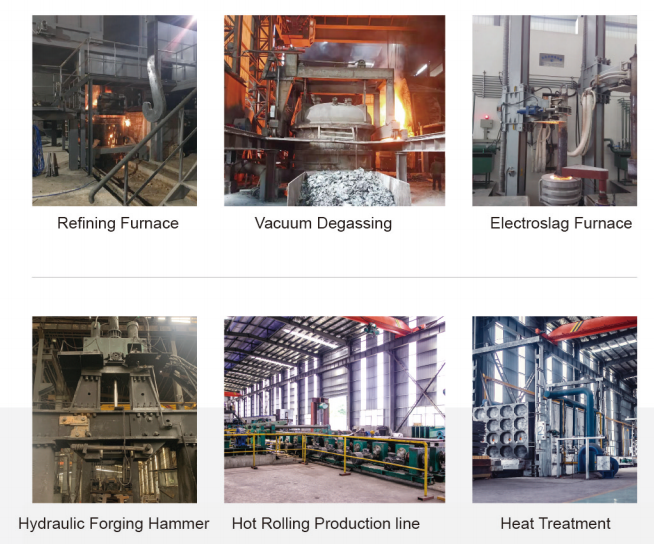

8. Equipment

Hongxin Mold Tech Co.,Ltd. owns 1 set of Hot Rolling Production Line at size range flats 8-80*210-710mm, rounds 16-50mm Dia.

12 sets of Hydraulic Forging Hammers from Power 560kgs to 6000kgs which could cover flats 40-300*210-710mm.

8 sets of EF+LF+VD

5 sets of ESR

9 sets of Milling Machines

10 sets of Turning Lathes

6 sets of Precision Milling Machines.

9. FAQ

Q1:Are you trading company or manufacturer ?

We are the biggest tool steel factory at Daye & Huangshi. We can provide a wide range of steel products.

Q2:What is alloy steel round bar export packing?

Usually bundling for large diameter,small diameter bars in bulk or as customer's demand.

Q3.What is your MOQ?

We accept small order,if it is stock,any quantities can be accepted.

Q4.What is your lead time?

Depends actual order,around 20-35 days,or negotiation.

Q5.Can you supply sample?

Yes,we can.Sample fee according to your size.

Q6:What certificates do you have?

ISO, ABS, BV, CCS, Dnv, Lr, Gl, Mill Certificate

Q7: How can I get your quotation as soon as possible?

The email and fax will be checked within 24 hours,meanwhile,the Skype,Wechat and WhatsApp will be online in 24 hours.Please send us your requirement,we will work out a best price soon.

10.Delivery condition

For hot forged or hot rolled round bar, usually the delivery condition is hot forged or rolled, annealed, rough turned.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface.

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

Contact Us Today for detailed specifications and competitive pricing!