Hongxin: DIN 1.2085 Steel Pioneer

2025-06-10 20:04In the competitive landscape of precision tooling and plastic mold manufacturing, the choice of steel can make or break product quality, durability, and production efficiency. DIN 1.2085 plastic mold steel (also known as X33CrS16 tool steel) stands out for its exceptional corrosion resistance, hardenability, and polishability, making it indispensable for industries demanding flawless surface finishes and long-lasting tooling. Hongxin, a leading DIN 1.2085 steel manufacturer based in China, has emerged as a trusted custom X33CrS16 mold steel supplier, delivering tailored solutions that meet the exacting standards of global clients.

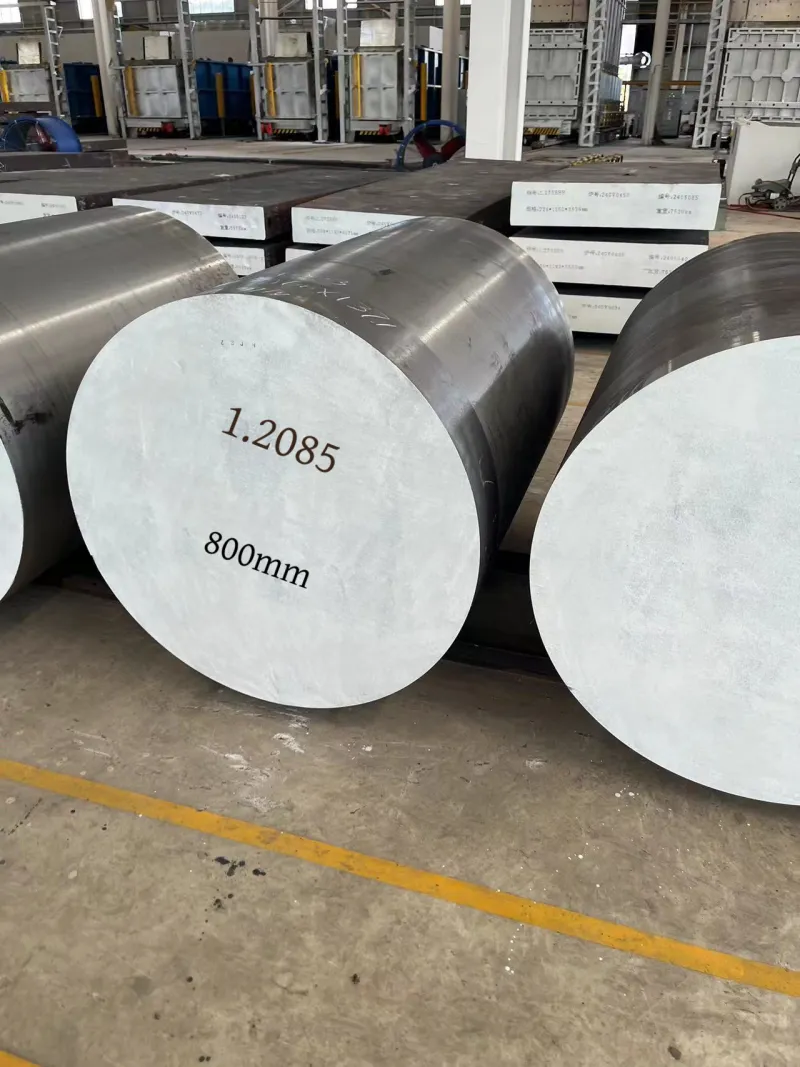

As a specialized manufacturer in China, Hongxin operates cutting-edge facilities equipped with advanced vacuum degassing, electroslag remelting (ESR), and precision forging technologies. Their production of DIN 1.2085 plastic mold steel adheres to stringent DIN and ISO specifications, ensuring uniform chemical composition, minimal impurities, and optimal mechanical properties. Whether clients require standard-sized bars or custom dimensions for complex mold designs, Hongxin’s in-house machining capabilities enable rapid prototyping and precise fabrication, reducing lead times and enhancing project flexibility.

The superiority of X33CrS16 tool steel lies in its balanced alloy composition—16% chromium provides corrosion resistance, while sulfur enhances machinability, making it ideal for high-gloss plastic molds, medical device components, and optical parts. Hongxin’s expertise in optimizing heat treatment processes further elevates the steel’s performance, achieving hardness levels up to 52 HRC without compromising toughness. This makes their DIN 1.2085 steel a preferred choice for automotive, electronics, and packaging industries, where mold longevity and dimensional stability are critical.

For businesses with niche requirements, Hongxin’s custom X33CrS16 mold steel offerings are unmatched. The brand collaborates closely with clients to adjust parameters like grain size, hardness distribution, and surface roughness, ensuring seamless integration into existing production workflows. Whether it’s a mold for transparent polycarbonate parts or a corrosion-resistant die for PVC injection, Hongxin’s technical team provides end-to-end support, from material selection to post-processing recommendations.

Hongxin’s China-based operations also offer cost advantages without sacrificing quality. By leveraging economies of scale and efficient supply chains, the brand delivers competitive pricing for bulk orders while maintaining rigorous quality control. Their custom solutions extend beyond steel grades—clients can request specialized packaging, certification documentation (such as EN 10204 3.1), and even pre-machined components to streamline their manufacturing processes.

In an industry where reliability and innovation are paramount, Hongxin’s commitment to excellence has solidified its reputation as a go-to DIN 1.2085 steel manufacturer and X33CrS16 tool steel supplier. By combining China’s manufacturing prowess with a focus on custom solutions, the brand not only meets but exceeds the evolving demands of modern tooling applications. For businesses seeking a partner that blends technical expertise with client-centric service, Hongxin offers a competitive edge in precision mold steel.